- Secondary Shredders

- NZS 700

- NZS 1000

- HEM 400 D

- HEM 1250

[rev_slider alias="carousel-nzs700"]

HAMMEL Secondary Shredder 700 |

|||

| Applications | |||

| Wood | waste wood, root stems, railway sleeper, pallets | ||

| Miscellaneous | paper rolls | ||

| Technical Data* | NZS 700 D | NZS 700 E | |

| Version | Hooklift | Electrical | |

| Engine | CAT C9.3 - Stage 5 | - | |

| Drive | 354 PS | 250 KW | |

| Weight | 19 t | 16 t | |

NZS 700 Datenblatt NZS 700 Datenblatt1.30 MB |

|||

| Functional principle | with high-speed shredding rotor and metal separation via metal detecto | ||

| Advantages |

|

||

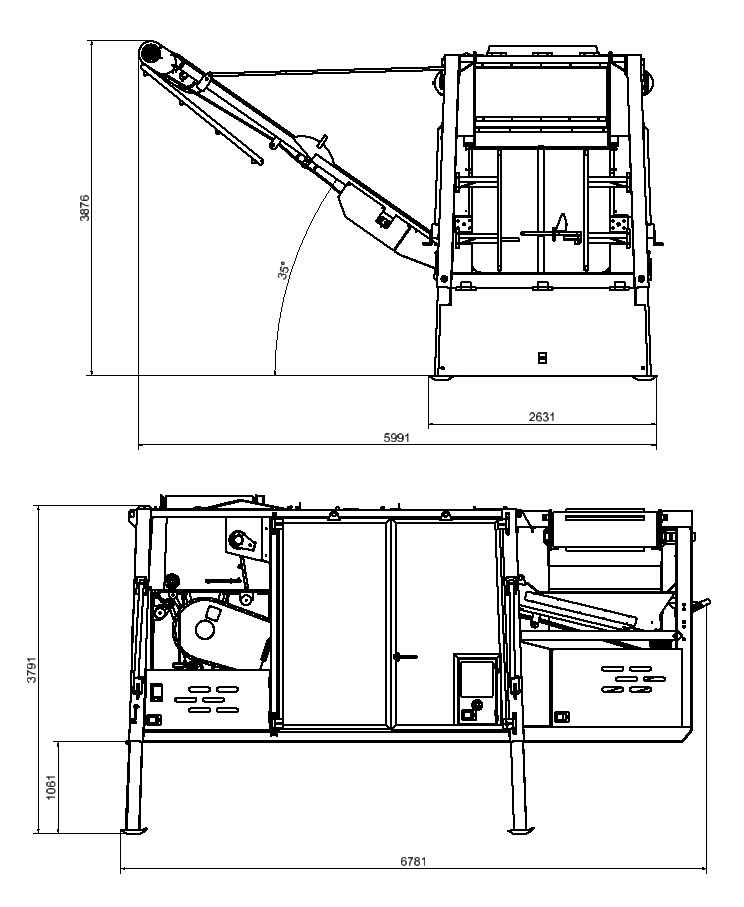

| Technical Drawing(Dimensions in mm) |  |

||

*approx. values; subject to change

[rev_slider alias="carousel-nzs1000"]

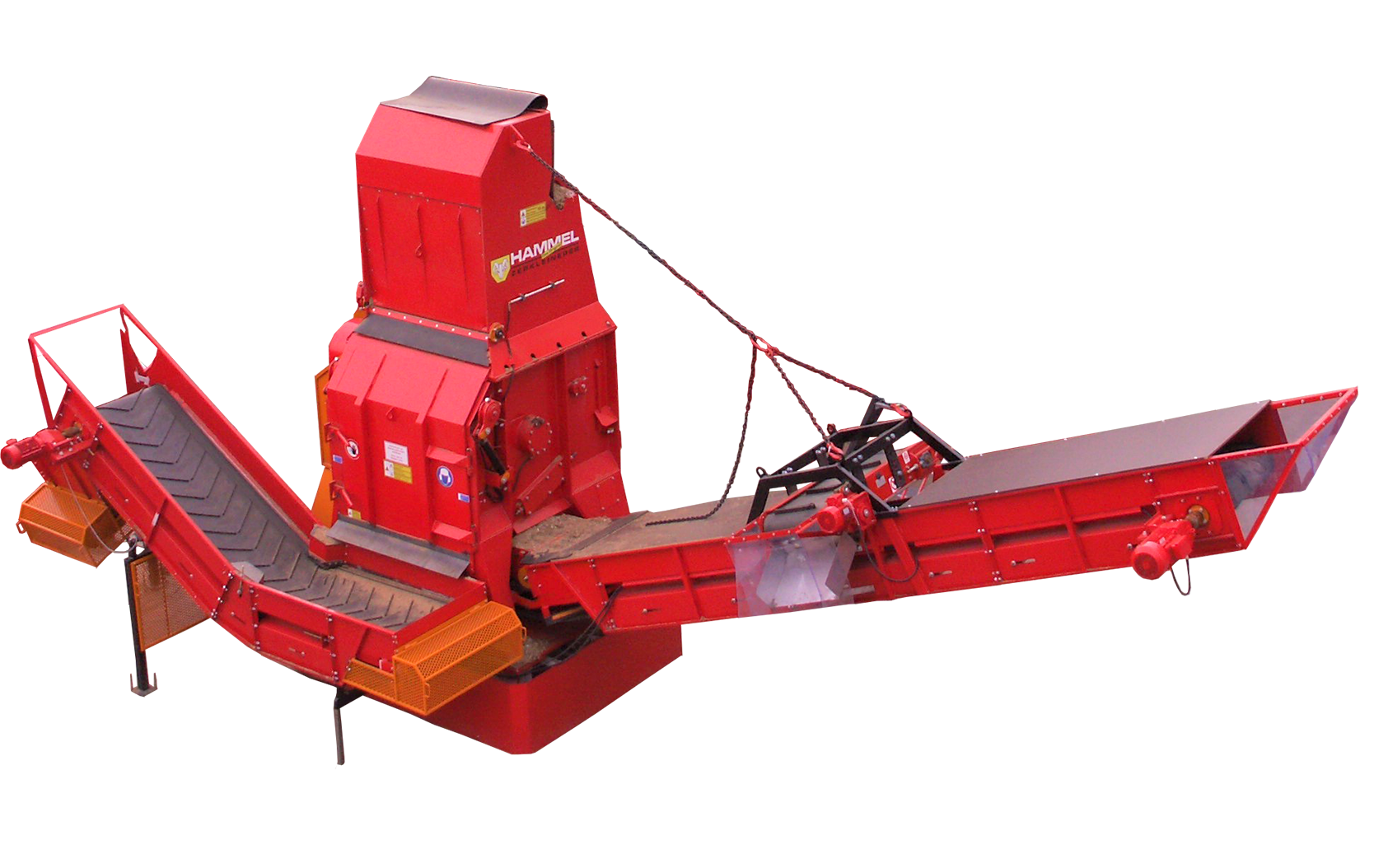

HAMMEL Secondary Shredder 1000 |

|||

| Applications | |||

| Wood | waste wood, root stems, green waste, railway sleeper, pallets | ||

| Miscellaneous | paper rolls | ||

| Technical Data* | NZS 1000 DK |

NZS 1000 E |

|

| Version | Chain | Stationary | |

| Drive | 525 PS | 350 KW | |

| Weight | 31 t | 25 t | |

NZS 1000 Datenblatt NZS 1000 Datenblatt1.30 MB |

|||

| Functional princple | high-speed metal separation | ||

| Advantages |

|

||

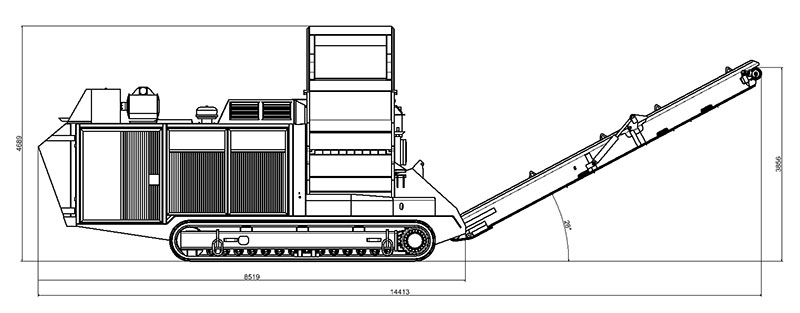

| Technical Drawing NZS 1000 E(Dimensions in mm) |  |

||

*approx. values; subject to change

[rev_slider alias="carousel-hem400"]

HAMMEL HEM 400 D |

|||

| Applications | |||

| Metal | aluminum profiles and bales, light metal scrap | ||

| Technical Data* | |||

| Version | Hooklift | ||

| Engine | Cummins B6.7 - Stage 5 | ||

| Drive | 350 PS | ||

| Weight | 13 t | ||

| Functional principle | The shredding is carried out by a belt directly into the shredding rotor. With a pre-tensioned screen basket, a precise final grain is achieved. A transverse magnet separates the exposed ferrous metals. | ||

| Advantages |

|

||

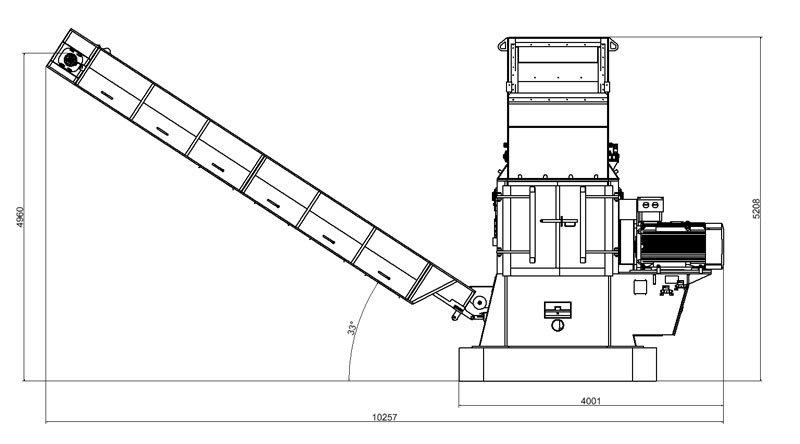

| Technical Drawing(Values in mm) |  |

||

*approx. values; subject to change

[rev_slider alias="carousel-nzs1250"]

HAMMEL HEM 1250 |

|||

| Applications | |||

| Metal | car bodies, aluminum profiles and bales, engine blocks, white goods, light metal scrap | ||

| Technical Data* | HEM 1250 DK |

HEM 1250 MD |

HEM 1250 E |

| Version | Chain | Magnet drum | Electrical |

| Drive | 710 PS | 710 PS | 510 KW |

| Weight | 49 t | 55 t | 50 t |

HEM 1250 DK Datenblatt HEM 1250 DK Datenblatt1.32 MB |

|||

| Functional principle | The shredding takes place through newly developed eccentric discs and the special shredding rotor. With a fittet screen basket a precise end product size is achieved. | ||

| Advantages |

|

||

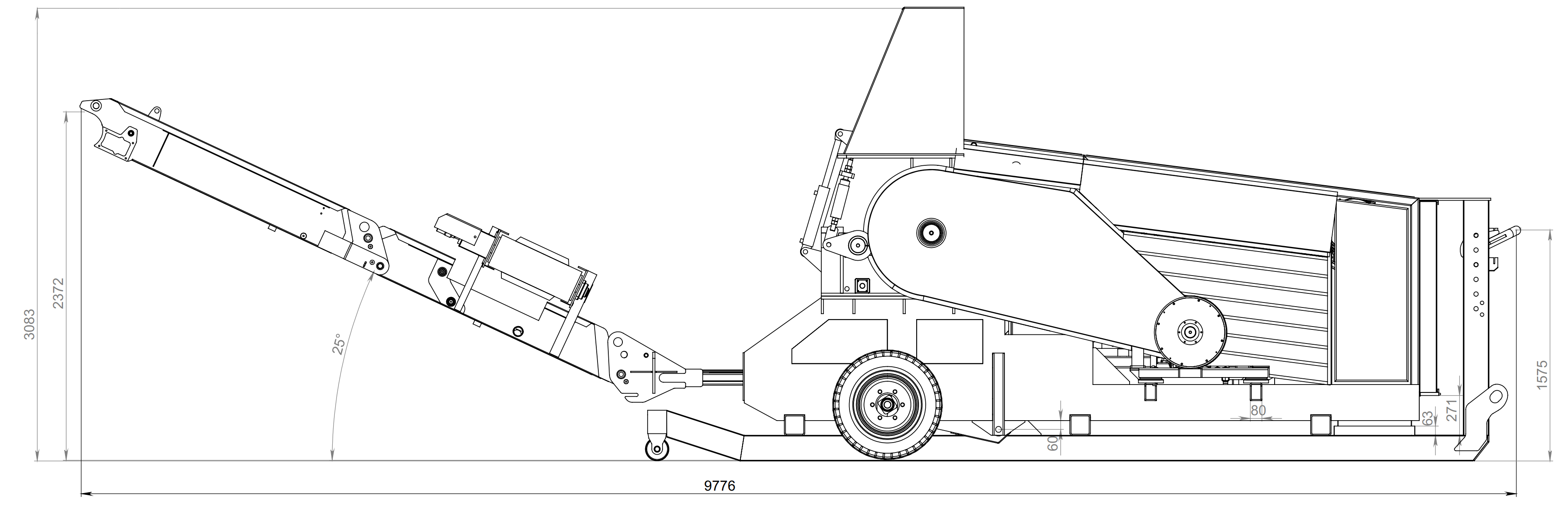

| Technical Drawing HEM 1250 DK(Values in mm) |

|

||

*approx. values; subject to change

English (UK)

English (UK)  Deutsch

Deutsch  Español

Español  Français

Français  Italiano

Italiano